Brown artificial marble has emerged as one of 2026's most sought-after materials for luxury residential and commercial projects. Unlike standard white or gray engineered stone, brown variations offer warm, earthy tones that create inviting spaces while maintaining the durability and consistency that artificial marble provides. Whether you're sourcing light brown artificial marble for a contemporary kitchen or dark brown artificial marble customized for a hotel lobby, understanding the nuances of color variations, customization options, and supplier capabilities is essential for project success.

This comprehensive guide explores everything architects, interior designers, and developers need to know about custom brown artificial marble. From the technical differences between light and dark variations to supplier selection criteria and current market trends, you'll gain actionable insights to make informed purchasing decisions. As global demand for warm-toned materials continues rising—particularly in North America, Australia, and Middle Eastern markets—knowing how to navigate the customization process and identify quality suppliers becomes increasingly valuable for high-end projects.

Understanding Brown Artificial Marble Variations

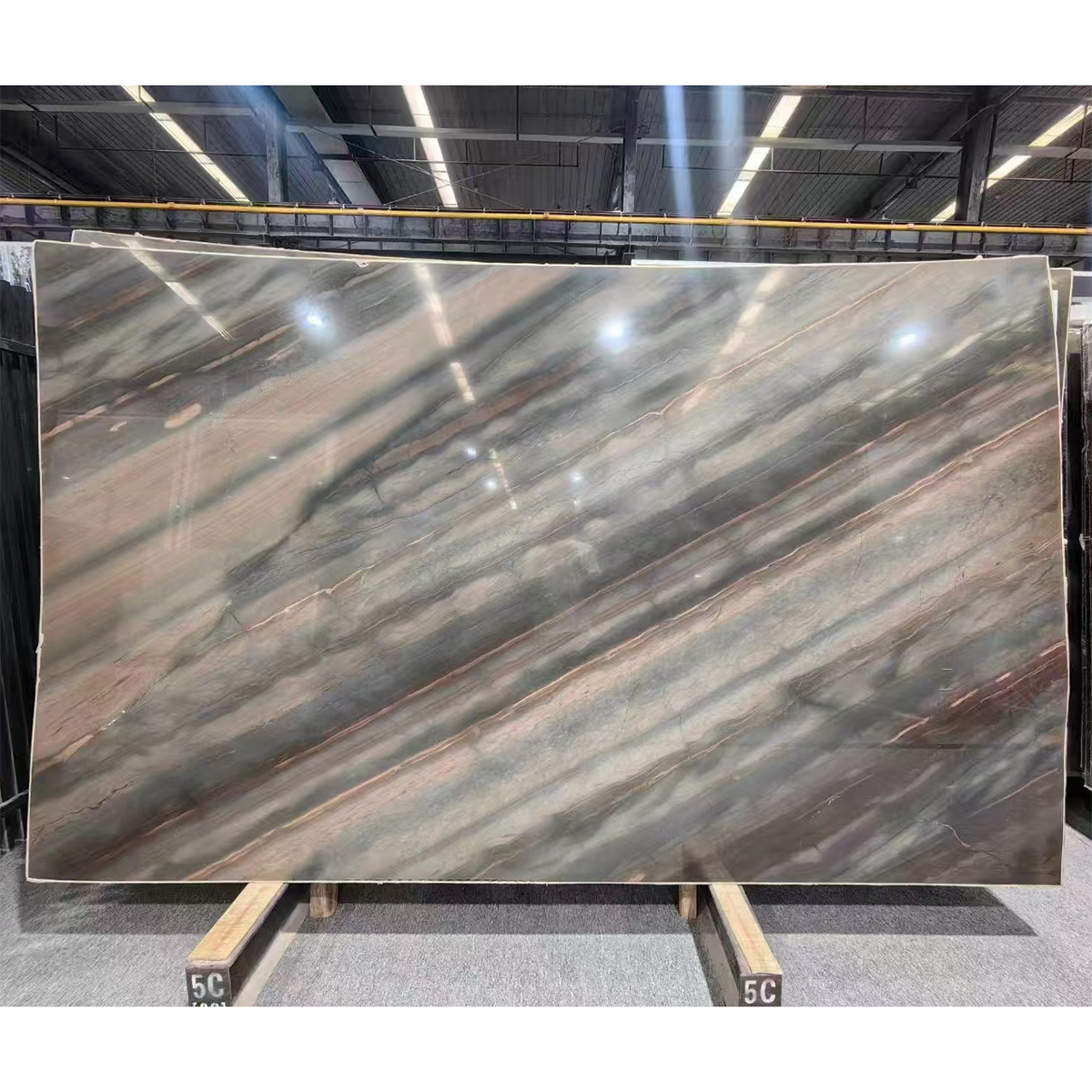

Brown artificial marble encompasses a wide spectrum of hues, from subtle honey beige to rich chocolate tones. The fundamental difference between light brown artificial marble and darker variations lies in the pigment composition and concentration used during the manufacturing process.

Light brown artificial marble typically contains lower concentrations of brown pigments mixed with white or cream base materials. This creates softer, more neutral tones that range from sandy beige to warm taupe. These lighter variations work exceptionally well in spaces where you want warmth without overwhelming the design scheme. They reflect more light than darker options, making them ideal for smaller rooms or areas with limited natural lighting.

Dark brown artificial marble features higher pigment concentrations, often incorporating multiple brown shades—from amber and cognac to deep espresso tones. Manufacturers may blend natural mineral oxides with resin bases to achieve rich, complex coloring that mimics high-end natural stones like Emperador or Crema Marfil varieties. The manufacturing process involves precise pigment mixing during the casting stage, where color consistency becomes paramount for large-scale projects.

One significant advantage of engineered brown marble over natural stone is color predictability. Natural brown marble deposits can vary dramatically in tone and veining patterns, even within the same quarry. INTERNAL: artificial marble slabs produced through controlled manufacturing processes ensure that every slab in your project maintains consistent coloring—a critical factor for commercial developments and luxury residences requiring visual uniformity across extensive installations.

Customization Options for Brown Engineered Marble

The ability to create customized dark brown artificial marble tailored to specific project requirements represents one of the material's most compelling advantages. Leading suppliers offer extensive customization services that go far beyond simply selecting from stock color options.

Color Matching and Custom Formulation

Professional suppliers provide color matching services where they can replicate specific brown tones from samples, existing materials, or even photographs. This process involves laboratory analysis of the desired shade, followed by custom pigment formulation. For projects requiring unique brown tones—perhaps matching existing architectural elements or brand color specifications—this capability proves invaluable. Expect a lead time of 2-4 weeks for custom color development, including sample approval.

Pattern and Veining Variations

Brown artificial marble can be manufactured with various aesthetic effects. Uniform patterns create solid brown surfaces with minimal variation—perfect for contemporary, minimalist designs. Alternatively, manufacturers can incorporate veining effects that simulate natural marble characteristics. These veins might be white, cream, gold, or even darker brown streaks running through lighter base materials. The veining pattern, density, and color can all be customized to match your design vision.

Size and Dimensional Customization

While standard slab dimensions typically measure 3000mm x 1400mm or 3200mm x 1600mm, suppliers offering customized light brown artificial marble can produce project-specific sizes. This includes:

- Jumbo slabs for seamless large-surface installations

- Pre-cut pieces for standardized applications like bathroom vanities

- Custom tile dimensions for unique flooring patterns

- Specialized cuts for furniture components

Surface Finish Options

The surface finish dramatically affects both aesthetics and functionality. Polished finishes provide high-gloss surfaces that enhance color depth and create luxurious appearances—ideal for lobby areas, feature walls, and high-end furniture. Honed finishes offer matte surfaces with subtle sheen, perfect for flooring where slip resistance matters. Leathered or textured finishes add tactile dimension while maintaining brown marble's inherent elegance.

Edge Treatments and Thickness

Thickness options typically range from 12mm for wall cladding to 30mm for heavy-duty applications like kitchen countertops. Edge profiles can be customized with beveled, bullnose, ogee, or waterfall treatments depending on the application. For furniture pieces like coffee tables or dining surfaces, specialized edge finishing becomes particularly important for both aesthetics and user comfort.

Applications and Design Uses

Brown artificial marble customized for specific applications offers remarkable versatility across residential and commercial projects. Understanding optimal use cases helps maximize the material's benefits while ensuring long-term performance.

Kitchen Countertops and Islands

Dark brown artificial marble excels in kitchen applications due to its superior stain resistance compared to natural stone. Coffee spills, wine splashes, and cooking oils—common culprits for staining lighter materials—blend more naturally with brown tones, maintaining the surface's pristine appearance with minimal effort. The non-porous nature of engineered marble prevents bacterial growth, making it ideal for food preparation areas. For luxury villa projects, waterfall-edge islands in rich brown tones create stunning focal points that anchor the kitchen design.

Flooring for High-Traffic Areas

Both commercial and residential flooring benefit from brown artificial marble's durability. Luxury hotel lobbies increasingly specify dark brown artificial marble for flooring because it maintains elegance while disguising the inevitable wear patterns that lighter materials reveal. The material's hardness rating and impact resistance ensure it withstands heavy foot traffic without cracking or chipping. In residential applications, open-concept living areas benefit from the warmth that brown marble flooring provides, creating cohesive flow between kitchen, dining, and living spaces.

Furniture Applications

The rising trend of stone furniture has positioned brown artificial marble as a premium choice for coffee tables, dining tables, console tables, and side tables. Unlike wood furniture that requires ongoing maintenance, engineered marble furniture pieces resist moisture, heat, and scratches. The material's workability allows for curved edges, integrated design elements, and precise fabrication that natural stone cannot easily achieve. For hospitality projects, brown marble furniture creates sophisticated atmospheres in lobbies, restaurants, and guest rooms.

Bathroom Vanities and Wet Areas

Bathroom applications showcase brown artificial marble's resistance to moisture and humidity. Vanity countertops in light brown tones complement various tile and fixture finishes, while darker variations create dramatic spa-like environments. Shower walls clad in brown engineered marble eliminate grout lines associated with tile installations, offering seamless, easy-to-clean surfaces. The material's thermal properties provide comfortable-to-touch surfaces even in temperature-fluctuating bathroom environments.

Accent Walls and Feature Elements

Architectural feature walls utilizing customized dark brown artificial marble transform ordinary spaces into memorable environments. Hotel lobbies, corporate reception areas, and luxury residential entryways benefit from the visual impact of floor-to-ceiling brown marble installations. Fireplace surrounds in warm brown tones create focal points that anchor living spaces while providing heat-resistant surfaces essential for fireplace applications.

Supplier Selection Criteria

Choosing the right supplier to supply light brown artificial marble significantly impacts project outcomes. Quality variations between manufacturers can be substantial, making careful supplier evaluation essential for high-end projects.

Quality Standards and Testing

Reputable suppliers provide comprehensive technical data sheets detailing material performance characteristics. Key metrics include:

- Barcol Hardness: Minimum 60 for commercial applications

- Heat Resistance: Should withstand temperatures up to 80°C without damage

- Impact Resistance: Measured via ball drop tests, quality products should resist cracking from typical impacts

- Water Absorption: Less than 0.5% for non-porous performance

- Flexural Strength: Minimum 40 MPa for structural applications

Request third-party laboratory certifications rather than relying solely on manufacturer claims. Independent testing from ISO-certified facilities provides objective quality verification.

Manufacturing Credentials and Certifications

Established suppliers maintain various industry certifications that indicate manufacturing quality and environmental responsibility. ISO 9001 certification demonstrates quality management systems, while ISO 14001 indicates environmental management practices. For projects targeting LEED certification or similar green building standards, suppliers should provide documentation of their products' environmental impact, including VOC emissions data and recycled content percentages.

Factory audits, either conducted personally or through third-party inspection services, reveal manufacturing capabilities and quality control processes. Look for facilities with automated production lines, climate-controlled curing environments, and multi-stage quality inspection protocols.

MOQ Requirements and Pricing Structures

Minimum order quantities vary significantly between suppliers. Large-scale manufacturers may require MOQs of 200-500 square meters for standard colors, while custom colors often necessitate higher minimums of 500-1000 square meters. Smaller suppliers or those specializing in custom work may accommodate lower volumes, though per-unit pricing typically increases.

Understanding pricing structures helps budget accurately. Suppliers typically offer tiered pricing where per-square-meter costs decrease at volume thresholds. When seeking to buy light brown artificial marble, request detailed quotes that specify:

- Base material cost per square meter

- Customization charges for non-standard colors or patterns

- Finishing and edge treatment costs

- Packaging and freight charges

- Payment terms and deposit requirements

Customization Capabilities and Lead Times

Not all suppliers offer equal customization capabilities. During evaluation, assess their color matching accuracy, pattern creation flexibility, and dimensional customization limits. Request samples of previous custom projects to evaluate quality and consistency.

Lead times significantly impact project schedules. Standard colors often ship within 2-3 weeks, while custom formulations require 4-8 weeks including sample approval cycles. For large projects requiring container loads, add manufacturing time (2-4 weeks) plus international shipping (3-6 weeks depending on destination).

Quality Control and Consistency

Batch-to-batch color consistency becomes critical for projects requiring multiple shipments. Suppliers should maintain detailed records of custom formulations and implement rigorous color matching protocols between production runs. Request information about their batch testing procedures and their policies for addressing color variance issues.

Warranty and After-Sales Support

Comprehensive warranty coverage protects your investment. Quality suppliers offer warranties covering manufacturing defects, typically 10-15 years for structural integrity and 5-10 years for color consistency. Clarify warranty terms regarding what constitutes covered defects versus normal wear or improper installation damage. After-sales technical support, including installation guidance and maintenance recommendations, adds value beyond the product itself.

Brown Artificial Marble vs Natural Stone

When evaluating dark brown artificial marble against natural brown marble varieties, several factors influence the optimal choice for specific projects.

Cost Considerations

Artificial marble typically costs 30-50% less than premium natural brown marble varieties like Dark Emperador or Brown Fantasy. This price advantage becomes more pronounced for large-scale projects where the material cost represents a significant budget component. Additionally, artificial marble's uniformity reduces waste during fabrication and installation, further decreasing total project costs. Transportation costs favor artificial marble as well—its lighter weight compared to natural stone reduces shipping expenses, particularly for international projects.

Performance Advantages

Engineered brown marble demonstrates superior stain resistance due to its non-porous structure. Natural marble requires sealing every 6-12 months to maintain stain resistance, while artificial marble needs no such treatment. The hardness and scratch resistance of quality artificial marble exceeds many natural stones, making it more suitable for high-traffic commercial applications.

Temperature tolerance presents another advantage. While natural marble can crack from rapid temperature fluctuations, properly manufactured artificial marble maintains structural integrity across wider temperature ranges. This makes it more reliable for applications near heat sources or in climate-variable environments.

Color Consistency Benefits

Perhaps the most significant advantage for large projects is color consistency. Natural brown marble deposits vary in color intensity, veining patterns, and background tones—sometimes dramatically within the same quarry. This variability creates matching challenges for projects requiring multiple shipments over extended periods. Artificial marble slabs manufactured from controlled formulations ensure visual consistency across entire installations, eliminating the risk of mismatched sections.

Maintenance Requirements

Artificial marble requires minimal maintenance—typically just regular cleaning with pH-neutral cleaners. Natural marble demands more attention, including periodic sealing, careful cleaning with stone-specific products, and professional restoration for etching or deep stains. For commercial projects, this maintenance differential translates to significant long-term cost savings and reduced operational complexity.

Environmental Factors

Environmental considerations present nuanced comparisons. Natural stone extraction impacts landscapes and ecosystems, while artificial marble manufacturing involves chemical processes and energy consumption. However, many modern manufacturers incorporate recycled materials and implement closed-loop water systems that minimize environmental impact. For projects pursuing green building certifications, both materials can contribute to sustainability goals when sourced from responsible suppliers.

Buying Guide and Pricing

Successfully purchasing customized light brown artificial marble requires systematic approaches to supplier engagement, sample evaluation, and order management.

Requesting Quotes and Specifications

Begin by preparing detailed project specifications including:

- Total square footage required

- Desired brown shade (provide visual references if possible)

- Thickness requirements

- Surface finish preferences

- Edge treatment specifications

- Delivery timeline and location

Contact multiple suppliers with identical specifications to enable accurate price comparisons. Request itemized quotes that separate material costs from customization charges, finishing work, and logistics. This transparency reveals where suppliers compete on price versus adding value through services.

Discount Opportunities for Volume Orders

Suppliers offering discount light brown artificial marble typically structure pricing around volume thresholds. Common break points occur at 100, 300, and 500 square meters. For projects approaching these thresholds, consider slightly increasing order quantities to capture lower per-unit pricing—the additional material cost often proves less than the per-unit savings achieved.

Timing purchases strategically can yield discounts. Many suppliers offer dark brown artificial marble promotions during slower business periods or when clearing inventory for new color launches. Building relationships with suppliers by consolidating purchases or committing to multi-project partnerships often unlocks preferred pricing tiers.

Light vs Dark Brown Pricing Differences

Generally, light brown artificial marble costs slightly less than darker variations because darker colors require higher pigment concentrations. However, this difference typically amounts to 5-10% rather than dramatic price disparities. Custom color formulations command premiums of 15-30% over standard offerings, reflecting the development work and smaller production runs involved.

Payment Terms and Logistics

Standard payment structures typically require 30-50% deposits upon order confirmation, with balance payment before shipping. For large orders, negotiate staggered payment terms tied to production milestones. Understand Incoterms clearly—FOB (Free on Board) pricing requires you to arrange and pay for international shipping and customs clearance, while CIF (Cost, Insurance, and Freight) includes delivery to your port. Door-to-door delivery services simplify logistics but increase costs.

Sample Evaluation Process

Never commit to large orders without evaluating physical samples. Request samples showing:

- The exact color formulation proposed for your project

- The specified surface finish

- Edge treatment examples if applicable

- Samples from recent production to assess current manufacturing quality

Evaluate samples under various lighting conditions—natural daylight, warm artificial lighting, and cool LED lighting—as brown tones appear dramatically different under various light sources. Test samples for stain resistance by applying coffee, wine, or oil and attempting to clean after several hours.

Installation Considerations

Factor installation costs into total project budgets. Professional installation typically costs $50-100 per square meter depending on project complexity and location. For furniture applications or complex architectural elements, specialized fabrication adds costs. Select contractors experienced with artificial marble installation—techniques differ slightly from natural stone, particularly regarding adhesive selection and seam placement.

Current Market Trends

The dark brown artificial marble customized market reflects broader shifts in interior design preferences and global construction activity.

Rising Demand for Warm Tones

2026's interior design landscape emphasizes warmth, comfort, and biophilic principles. Brown marble tones align perfectly with these trends, offering earthy alternatives to the cool grays and stark whites that dominated previous years. Design publications increasingly feature brown stone materials in luxury residential projects, driving consumer demand. This trend appears particularly strong in post-pandemic design philosophies prioritizing home comfort and wellness.

Hospitality and Residential Project Growth

The global hospitality sector's recovery continues driving demand for brown artificial marble. Hotels, resorts, and restaurants specify these materials for lobbies, restaurants, and guest bathrooms where warmth and luxury intersect. High-end residential developers, particularly in luxury villa projects across Mediterranean, Middle Eastern, and Southeast Asian markets, increasingly incorporate brown engineered marble for both durability and aesthetic appeal.

The residential renovation market also contributes to demand growth. Homeowners updating kitchens and bathrooms frequently select brown marble countertops and backsplashes, appreciating both the material's performance characteristics and design flexibility.

Regional Market Preferences

North American markets show strong preference for lighter brown tones in residential applications, often paired with white cabinetry and contemporary fixtures. Australian projects trend toward mid-tone browns that complement the region's coastal aesthetic and natural material preferences. Middle Eastern markets, particularly UAE and Saudi Arabia, specify darker, more dramatic brown marbles for luxury residential and hospitality projects where opulence and statement design prevail.

European markets demonstrate varied preferences—Mediterranean regions favor warmer browns, while Northern European projects often specify cooler brown-gray combinations. Understanding these regional preferences helps suppliers tailor offerings and marketing approaches.

Integration with Design Styles

Brown artificial marble's versatility enables integration across design styles. Contemporary projects utilize it for clean-lined countertops and minimalist furniture pieces. Traditional designs incorporate brown marble for classic elegance in fireplace surrounds and ornate bathroom vanities. Transitional styles—currently among the most popular residential design approaches—leverage brown marble as a bridge between traditional warmth and contemporary simplicity.

The material's compatibility with both warm and cool color palettes expands design possibilities. Light brown variations complement cream, beige, and soft gray color schemes, while dark brown artificial marble pairs beautifully with charcoal, navy, and rich jewel tones increasingly popular in luxury interiors.

Conclusion

Custom brown artificial marble represents a sophisticated material choice that balances aesthetic appeal, practical performance, and design flexibility. Whether you're sourcing light brown artificial marble for residential elegance or dark brown artificial marble customized** for commercial impact, understanding the nuances of color variations, customization options, and supplier capabilities empowers informed decision-making.

The advantages of engineered marble—consistent coloring, superior stain resistance, lower maintenance requirements, and cost-effectiveness—make it increasingly attractive for architects, designers, and developers working on high-end projects. As 2026's design trends continue emphasizing warm, inviting spaces, brown marble variations position themselves as essential materials for creating environments that resonate with contemporary aesthetic preferences while delivering lasting performance.

For your next project, carefully evaluate suppliers based on quality standards, customization capabilities, and service comprehensiveness rather than price alone. Request samples, verify certifications, and establish clear specifications before committing to orders. The investment in thorough supplier vetting and material selection pays dividends through successful installations that meet aesthetic visions and performance requirements.

Explore Future Stone Group's collection of premium engineered marble options, including specialized brown artificial marble products designed for luxury applications. With comprehensive customization services, rigorous quality standards, and global delivery capabilities, finding the perfect brown marble variation for your project becomes an achievable goal rather than a daunting challenge.